Why Is My Sewing Machine Jamming? An Expert’s Guide to Finding and Fixing the Cause

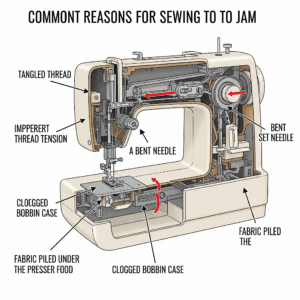

You’re sewing a seam, and suddenly you hear it: a clunking, grinding sound as the machine groans to a halt, the handwheel completely locked. You’ve got a jam. This frustrating experience is universal to everyone who sews, from absolute beginners to seasoned professionals. The good news is that a jam is rarely a sign of a truly broken machine.

In almost every case, a jam is a symptom of a simple setup issue. This expert troubleshooting guide will walk you through the most common causes in order of likelihood, helping you diagnose the problem, fix it safely, and get back to sewing smoothly.

The #1 Cause of Jams: The “Bird’s Nest” & Threading Errors

The most common type of jam is the dreaded “bird’s nest”—a massive, tangled mess of thread that forms under your fabric in the bobbin area. This tangle physically seizes the hook mechanism, locking up the machine.

The Expert’s Secret: A bird’s nest of thread on the **bottom** of your fabric is almost always caused by a problem with the **top thread**. Specifically, it means your top thread has no tension. When the needle goes down, the bobbin hook pulls a huge, loose loop of the untensioned top thread, creating a massive tangle that instantly jams the machine.

The most common reason for this lack of tension is simple: **threading the machine with the presser foot down.** The tension discs that control the top thread are only open when the presser foot is lifted up. If you thread the machine with the foot down, the thread rests on the outside of these closed discs, resulting in zero tension.

The Fix: Lift the presser foot. Unthread the top thread completely. Carefully re-thread your machine, ensuring the thread “clicks” or seats firmly between the tension discs.

The Silent Culprit: Lint Buildup

Every time you sew, tiny fibers from your thread and fabric break off and create lint. Over time, this lint gets packed tightly into the bobbin area and around the feed dogs. In a humid environment like Dhaka, this lint can absorb moisture and become even more compact. This packed lint obstructs the moving parts of your machine, creating friction and eventually causing it to seize up and jam.

The Fix: Perform regular cleaning. Turn off and unplug your machine, then remove the needle plate and bobbin case. Use a small, stiff brush to sweep out all visible lint. Regular cleaning is the best preventative maintenance you can do.

1. Sewing Machine Maintenance & Cleaning Kit

Having the right tools makes preventing jams easy. A dedicated maintenance kit with small brushes of different shapes, tweezers for grabbing tangled threads, and screwdrivers for removing the needle plate is an essential accessory for every sewist.

Check Price on AmazonThe Wrong Tools for the Job: Needle & Thread Issues

Using the wrong consumables for your project is another frequent cause of jams.

- A Dull or Bent Needle: A dull needle doesn’t pierce fabric cleanly; it punches through it. This can push the fabric down into the bobbin area, causing a jam. A slightly bent needle can strike the metal bobbin case, causing the machine to lock up instantly. **The Fix:** When in doubt, start your troubleshooting by installing a brand new needle.

- Poor Quality Thread: Cheap thread is often weak and produces a large amount of lint. This lint contributes directly to the buildup that causes jams, and the thread is more likely to snap and get tangled in the mechanism. **The Fix:** Invest in good quality thread from a reputable brand.

2. High-Quality Needle Variety Pack

Starting every project with a fresh, sharp needle of the correct type (e.g., a Jeans needle for denim) is the best insurance against jams. A bent or dull needle is a primary culprit. A variety pack ensures you always have the right tool for the job.

Check Price on AmazonHow to Safely Unjam Your Machine: A Step-by-Step Process

When the machine is physically locked, follow these steps to free it without causing damage.

- Turn Off the Power! This is the most important safety step. Unplug the machine if possible.

- Cut All Visible Threads. Snip the top thread above the needle and the bobbin thread under the fabric to release all tension.

- Raise the Needle. Gently turn the handwheel **towards you** (never away from you). You may feel some resistance as you break through the thread nest. This should lift the needle and allow you to slide the fabric out.

- If the Handwheel is Stuck Solid: Do not force it. Remove the needle plate and bobbin case first. This will give you direct access to the tangled thread. Use tweezers or small scissors to carefully cut away the entire thread nest until the mechanism is free.

- Diagnose and Fix. Once the machine is unjammed, follow the advice in the sections above: completely re-thread the machine (with the presser foot up!), clean the bobbin area thoroughly, and install a brand new needle.

Conclusion: Jams are Signals, Not Failures

Think of a sewing machine jam not as a failure, but as a clear signal that something in the setup needs your attention. By understanding the common causes—improper threading, lint buildup, or a worn-out needle—you can quickly diagnose and solve the problem yourself. By developing good habits like regular cleaning and always starting a project with a fresh needle, you can prevent most jams from ever happening. With this knowledge, you can approach your sewing with confidence, ready to handle any issue that arises.